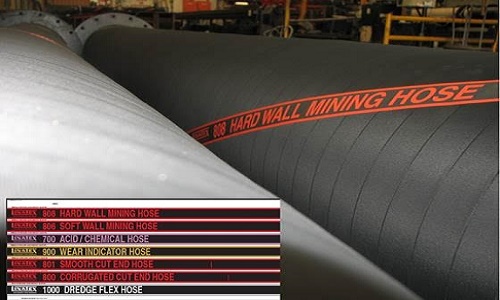

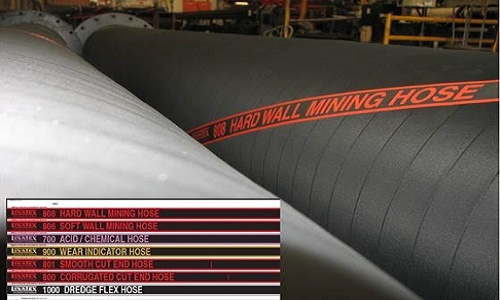

LINATEX hoses and elbows are resistant to abrasion and are usually designed and manufactured by the customer’s order to carry various high-abrasive mineral slurry from natural rubber, which is the result of 90 years of the company’s activity. Different design and proven performance of LINATEX hoses has made it the first choice for world large mining companies.

Rubber hoses are produced with the following general features:

Internal diameter (ID) 32 to 1042 mm

The working pressure manufactured hoses is at least 7 bars

For various applications including material handling of abrasive minerals in mines and mining and dredging industries (Dredge Hoses)

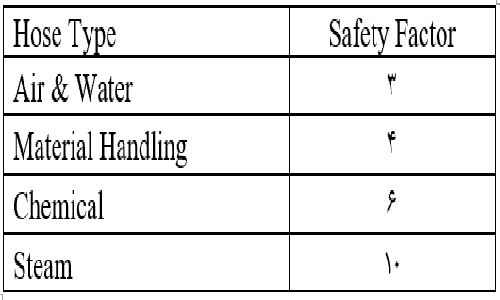

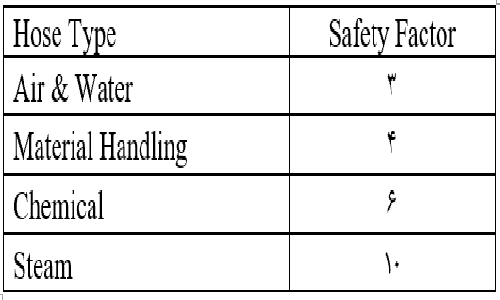

Depending on the type of application, the pipes are made with wire and without it, according to the following parameters:

-

Elbows and rubber converters are manufactured with the following general features:

LINATEX elbows are used in places that require a greater radius of deflection due to spatial constraints.

Due to its special design, they have much higher abrasion resistance than metal types and even ordinary rubber pipes.

Internal diameter (ID) 38 to 1100 mm

LINATEX elbows are supplied in a wide range of shapes, diameters, bending angles and radians.