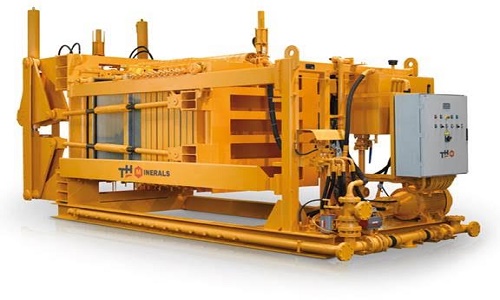

Filter presses are made with two technologies, membrane technology (MFP) and chamber (CFP), which both are used for dewatering. The difference is that chamber filters are commonly used in the food industries, and membrane filters are used in mineral dewatering and water treatment, which puts more pressure on the cake by applying pressure from the inside.

TH company (Spain) has more than 45 years of experience in designing and supplying various types of membrane concentrate and tail filter presses, filter cloths and diaphragm pumps, and has delivered its various products to its employers in Iran including to metal and non-metallic mineral processing plants for more than.

Choosing the right pump for filtration systems is very important in the proper operation of different types of filter press systems in solid liquid separation. TH manufactures special diaphragm pump that can transfer abrasive mineral slurry to the filtration system at the required pressure. The most important features of this type of pump are:

– Providing required working pressure up to 10 bar

– Lower power consumption compared to centrifugal pumps

– Ability to maintain pressure stability with slow pump movement

– Does not affect the performance of flocculant due to the lateral movement of pump

– Because it has only one moving part, abrasive parts consumption is very low compared to centrifugal pumps